What is the working principle of CFR-50JB-52-1M6?

What is the working principle of CFR-50JB-52-1M6?

The CFR-50JB-52-1M6 is a carbon film resistor designed to regulate current flow in electronic circuits. Its working principle relies on a helical groove etched into the resistive carbon film. This groove increases the path electrons travel, precisely defining resistance. Such innovations meet the growing demand for stable, reliable components in modern electronics.

Key Takeaways

- The CFR-50JB-52-1M6 is a carbon film resistor. It controls how much current flows in electronic circuits. Its spiral groove shape makes the path for electrons longer, which sets its resistance.

- This resistor is strong and low-cost, so it works well in cars, home gadgets, and factory machines. Its through-hole design makes it tougher for hard conditions.

- Changes in temperature can change how the resistor works. But its ceramic base helps keep it steady. Always check the temperature rating to match it with your circuit.

Overview of the CFR-50JB-52-1M6

### What is the CFR-50JB-52-1M6?

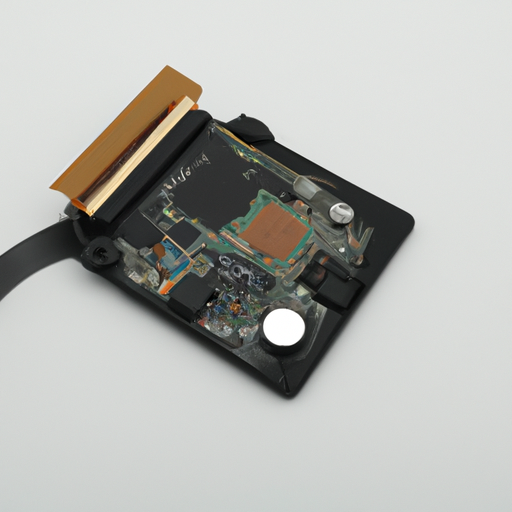

The CFR-50JB-52-1M6 is a type of carbon film resistor. It plays a critical role in controlling the flow of current in electronic circuits. You’ll find it designed with a resistive carbon film layer wrapped around a ceramic rod. This structure ensures durability and consistent performance. A helical groove etched into the carbon film adjusts the resistance value, making it suitable for a wide range of applications.

This resistor is known for its reliability and affordability. It offers a balance between performance and cost, making it a popular choice in various industries. While it may not match the precision of metal-based resistors, its simplicity and effectiveness make it indispensable in many electronic systems.

General purpose and significance in electronics

The CFR-50JB-52-1M6 serves as a fundamental component in electronic circuits. Its primary purpose is to limit current flow, protecting sensitive components from damage. You’ll often see it used in devices where stable resistance is essential.

However, like other carbon film resistors, it faces some challenges:

- Stability issues under varying temperatures.

- Sensitivity to temperature fluctuations, which can affect performance.

- Inductance caused by the helical cut, which may impact high-frequency applications.

- Limited resistance range compared to metal-based resistors.

Despite these challenges, the CFR-50JB-52-1M6 remains significant. Its working principle, based on the helical groove and resistive film, ensures reliable performance in most standard applications. Its through-hole mounting design also enhances durability, making it ideal for long-term use in consumer electronics, industrial devices, and automotive systems.

Key components and their roles

### Carbon film and its resistive properties

The carbon film in the CFR-50JB-52-1M6 plays a crucial role in defining its resistance. This thin layer of carbon, deposited on a ceramic rod, acts as the primary resistive element. You’ll notice that carbon film resistors are known for their ability to handle high-energy pulses, making them suitable for surge protection and high-frequency circuits. However, they generate more thermal noise compared to metal film resistors, which limits their use in sensitive applications like audio equipment.

When comparing carbon film to other materials, you’ll find some key differences:

- Carbon film resistors have a higher temperature coefficient of resistance (TCR), ranging from -200 to -1000 ppm/k. This makes them less stable under extreme temperatures than metal film resistors.

- They exhibit a voltage coefficient of resistance (VCR) of -10 ppm/V, which is higher than the near-zero VCR of metal film resistors.

- While they are moderately stable, they don’t match the exceptional stability of metal film resistors.

Despite these limitations, the carbon film’s durability and ability to withstand energy pulses make it a reliable choice for many applications.

Ceramic rod as the structural base

The ceramic rod serves as the backbone of the CFR-50JB-52-1M6. It provides a sturdy base for the carbon film, ensuring the resistor maintains its shape and performance over time. You’ll appreciate how the ceramic material resists heat and mechanical stress, which enhances the resistor’s durability. This structural integrity makes the resistor suitable for long-term use in demanding environments like industrial devices and automotive systems.

Helical groove and its role in resistance definition

The helical groove etched into the carbon film is what defines the resistor’s value. By increasing the path electrons must travel, the groove effectively raises the resistance. You can think of it as a way to fine-tune the resistor’s performance. The design also helps distribute heat evenly, reducing the risk of localized overheating. However, the helical cut introduces a small amount of inductance, which may affect performance in high-frequency applications.

This combination of carbon film, ceramic rod, and helical groove ensures the CFR-50JB-52-1M6 delivers reliable performance across a wide range of applications.

Step-by-step explanation of the working principle

### How the resistive film limits current flow

The resistive film in the CFR-50JB-52-1M6 plays a key role in controlling current. When electricity flows through the resistor, the carbon film resists the movement of electrons. This resistance reduces the current to a safe level for the connected components. You can think of it as a checkpoint that ensures only the right amount of current passes through.

The thickness and material of the carbon film determine how much resistance it provides. A thinner film increases resistance, while a thicker one allows more current to flow. This design makes the resistor versatile for different applications.

Role of the helical groove in determining resistance

The helical groove etched into the carbon film fine-tunes the resistor's value. By creating a longer path for the electrons, the groove increases resistance. Imagine a winding road that slows down traffic; the helical groove works in a similar way for electrons.

You’ll notice that the depth and spacing of the groove directly affect the resistance. A deeper or more closely spaced groove increases the resistance, while a shallower one reduces it. This precise adjustment ensures the resistor meets specific requirements for various circuits.

Impact of temperature coefficient on performance

Temperature changes can affect the resistor’s performance. The carbon film has a temperature coefficient, meaning its resistance changes with temperature. As the temperature rises, the resistance may increase or decrease slightly.

This variation can impact sensitive circuits, especially in high-temperature environments. However, the ceramic rod base helps stabilize the resistor by dissipating heat efficiently. You can rely on the CFR-50JB-52-1M6 for consistent performance in most standard applications, despite minor temperature-related fluctuations.

Practical applications and use cases

### Use in automotive electronics (AEC-Q200 qualification)

The CFR-50JB-52-1M6 plays a vital role in automotive electronics. Its AEC-Q200 qualification ensures it meets the rigorous standards required for automotive applications. You’ll find it used in systems like engine control units, lighting circuits, and infotainment systems. These environments demand components that can withstand high temperatures, vibrations, and electrical stress.

This resistor’s ceramic base and carbon film construction make it reliable under such conditions. Its ability to handle energy pulses and maintain stability ensures consistent performance. If you’re working on automotive designs, this resistor offers a dependable solution for current regulation and circuit protection.

> **Tip:** When designing automotive circuits, always look for components with AEC-Q200 certification to ensure durability and compliance with industry standards.

Applications in consumer electronics and industrial devices

You’ll also see the CFR-50JB-52-1M6 in consumer electronics like televisions, audio systems, and power supplies. Its affordability and reliability make it a popular choice for these devices. In industrial settings, it’s used in control panels, motor drives, and power distribution systems.

The resistor’s ability to handle moderate temperature fluctuations and energy surges makes it suitable for these applications. Its helical groove design ensures precise resistance, which is crucial for maintaining circuit stability in both consumer and industrial devices.

Benefits of through-hole mounting for reliability

The through-hole mounting design of the CFR-50JB-52-1M6 enhances its durability. This method creates a strong mechanical bond between the resistor and the circuit board. You’ll notice this feature is especially beneficial in environments with high vibrations or mechanical stress, such as automotive and industrial systems.

Through-hole mounting also simplifies the soldering process, making it easier to achieve a secure connection. If you’re looking for a resistor that combines reliability with ease of installation, this design is an excellent choice.

> **Note:** While surface-mount resistors are common, through-hole resistors like the CFR-50JB-52-1M6 offer superior mechanical strength, making them ideal for demanding applications.

The working principle of the CFR-50JB-52-1M6 revolves around its resistive carbon film and helical groove, which precisely control current flow. This design ensures reliable performance in electronic systems, making it a trusted choice for diverse applications. Future advancements may focus on improving long-term stability, reducing noise levels, and enhancing temperature response. You can explore its use in automotive, consumer, and industrial devices to meet your circuit needs.

FAQ

### What makes the CFR-50JB-52-1M6 different from other resistors?

The helical groove design sets it apart. It fine-tunes resistance by increasing the electron path, ensuring precise current control in various applications.

Can the CFR-50JB-52-1M6 handle high temperatures?

Yes, its ceramic rod base dissipates heat efficiently. This feature makes it suitable for environments with moderate to high temperatures, like automotive and industrial systems.

> **Tip:** Always check the resistor's temperature coefficient for compatibility with your application.

Is the CFR-50JB-52-1M6 suitable for high-frequency circuits?

Not always. The helical groove introduces slight inductance, which may affect performance in high-frequency applications. For such cases, consider metal film resistors instead.

> **Note:** Evaluate your circuit's frequency requirements before selecting a resistor.